Airport Pushback Tractors - Ground Support Equipment (GSE)

Airport Ground Equipment and Aircraft Pushback Tractors

Airport ground equipment plays a vital role in the safe, efficient and timely operation of modern airports. From aircraft parking to departure, a wide range of specialised ground support equipment (GSE) is required to ensure aircraft are handled correctly while on the apron. Among the most critical types of airport ground equipment are aircraft pushback tractors, which are essential for manoeuvring aircraft safely away from gates and stands.

What Is Airport Ground Equipment?

Airport ground equipment, often referred to as ground support equipment (GSE), includes all vehicles and machinery used to service aircraft while they are on the ground. This equipment supports aircraft operations without the use of engines, helping airports improve safety, efficiency and environmental performance.

Common types of airport ground equipment include:

Aircraft pushback tractors

Baggage loaders and belt loaders

Aircraft refuelling tankers

Passenger stairs and boarding bridges

Ground power units (GPU)

De-icing and anti-icing vehicles

Each category of ground equipment is designed to perform a specific function, but pushback tractors are among the most visible and operationally critical assets on the airport apron.

The Role of Aircraft Pushback Tractors

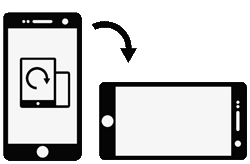

Aircraft pushback tractors are used to move aircraft backwards from parking positions, gates or stands before taxiing. Most commercial aircraft cannot reverse under their own power safely or efficiently, making pushback tractors an essential part of airport ground operations.

These vehicles connect to the aircraft’s nose landing gear, either via a towbar or using a towbarless system, allowing precise control during pushback. Pushback tractors are operated by trained personnel and coordinated closely with flight crews and air traffic control.

Types of Aircraft Pushback Tractors

There are two main categories of aircraft pushback tractors used at airports worldwide:

Towbar Pushback Tractors

Towbar tractors use a detachable towbar to connect the tractor to the aircraft’s nose gear. This traditional method is widely used and remains popular due to its flexibility across different aircraft types.

Towbarless Pushback Tractors

Towbarless tractors lift and cradle the aircraft’s nose wheel, eliminating the need for a separate towbar. These pushback tractors offer faster connection times, reduced equipment handling and improved manoeuvrability, making them increasingly popular at busy airports.

Benefits of Modern Pushback Tractors

Modern aircraft pushback tractors are designed with safety, efficiency and environmental considerations in mind. Key benefits include:

Enhanced safety through improved visibility, braking systems and control

Operational efficiency, reducing turnaround times at gates

Compatibility with a wide range of aircraft, from regional jets to widebody aircraft

Reduced emissions, with electric and hybrid pushback tractors becoming more common

Lower operating costs due to improved reliability and reduced maintenance requirements

As airports focus on sustainability and performance, investment in advanced pushback tractors is becoming increasingly important.

Pushback Tractors and Airport Efficiency

Efficient aircraft movement on the ground is critical to maintaining airport schedules and reducing delays. Pushback tractors allow precise positioning of aircraft while minimising engine use, which helps lower fuel consumption and reduce noise on the apron.

At congested airports, reliable airport ground equipment such as aircraft pushback tractors plays a key role in maximising gate utilisation and improving overall airside operations.

Choosing the Right Pushback Tractor

Selecting the right aircraft pushback tractor depends on several factors, including:

Aircraft types and weights handled

Airport layout and apron space

Environmental and emissions requirements

Frequency of operations and peak traffic periods

Airports, ground handling companies and airlines must ensure their pushback tractors meet operational demands while complying with safety regulations and industry standards.

The Future of Airport Ground Equipment

The future of airport ground equipment is moving towards electrification, automation and improved sustainability. Electric aircraft pushback tractors are increasingly adopted to reduce carbon emissions and support airport environmental targets.

Advancements in telematics, diagnostics and operator assistance systems are also improving the safety and reliability of pushback operations, ensuring aircraft ground handling continues to evolve alongside modern aviation demands.

Aircraft Tugs – Current stock

Request a Quote

Select one or more items using “Add to quote”. When finished, return here and click Request a Quote. Click an image to view the item.